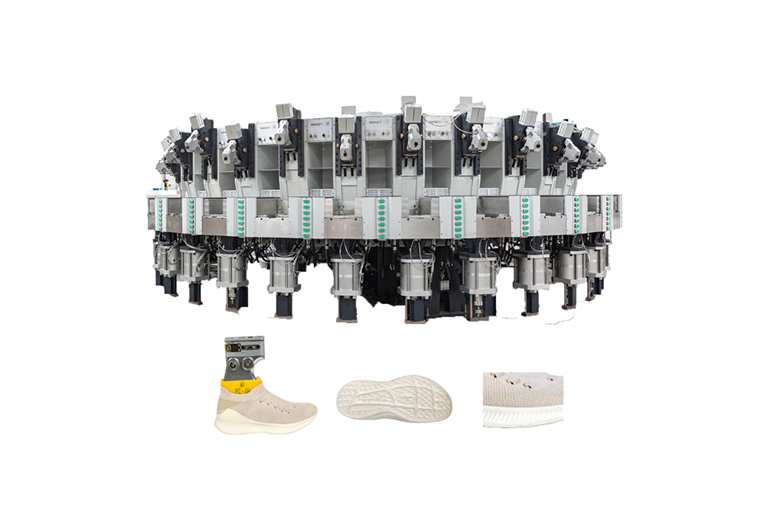

Injection shoe making machine

Share

Product Details

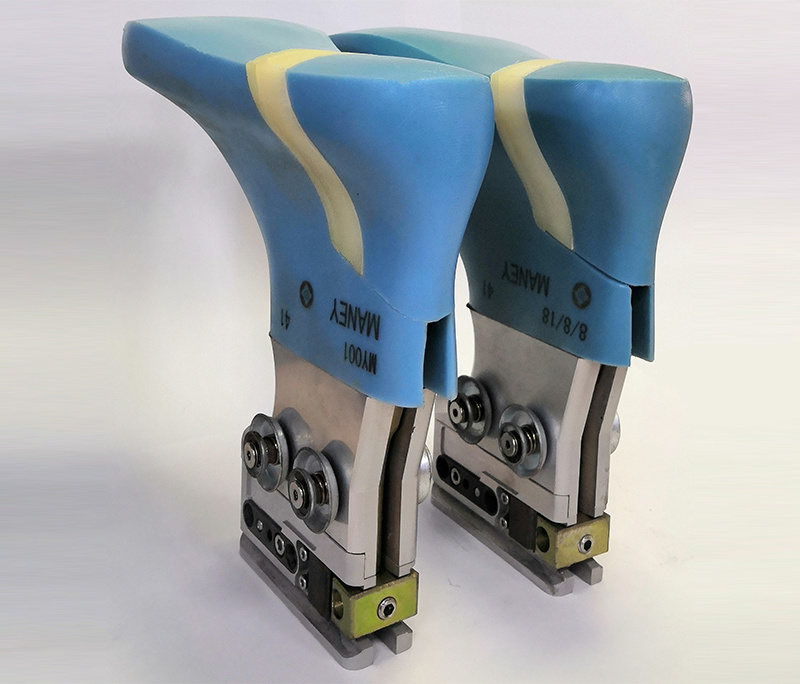

I. "PU/PU Direct Injection Shoe Making Machine"

1. Used for direct injection molding of single-density and dual-density multicolor PU soles onto uppers;

2. The PU screw mixing system is high-temperature resistant, low-noise, and high-speed, ensuring optimal mixing results;

3. Wear-resistant, high-precision metering pumps use a high-speed control system to ensure reliable, safe, and precise metering;

4. Simple and fast injection system improves productivity;

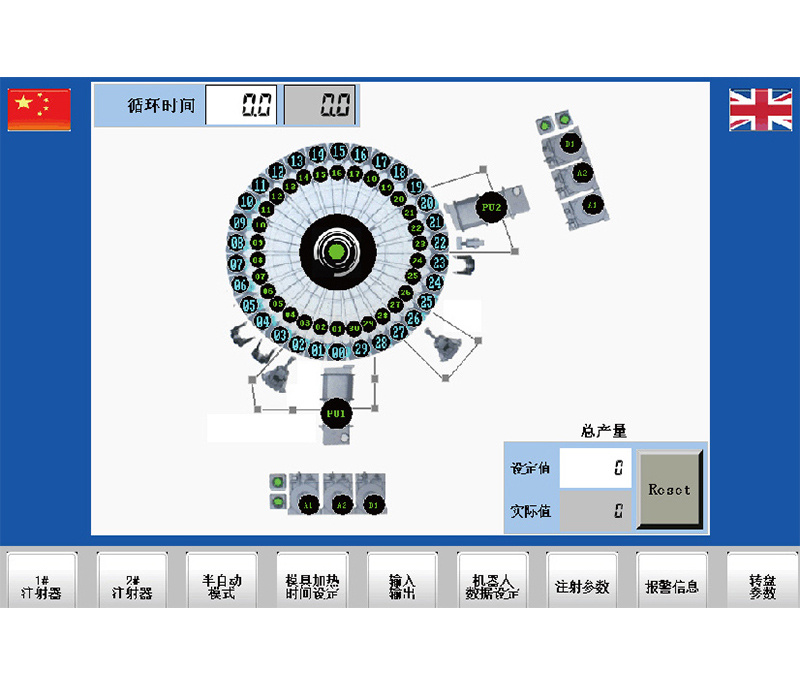

5. Parameters of each station can be freely programmed;

6. Remote control system for machine maintenance and service.

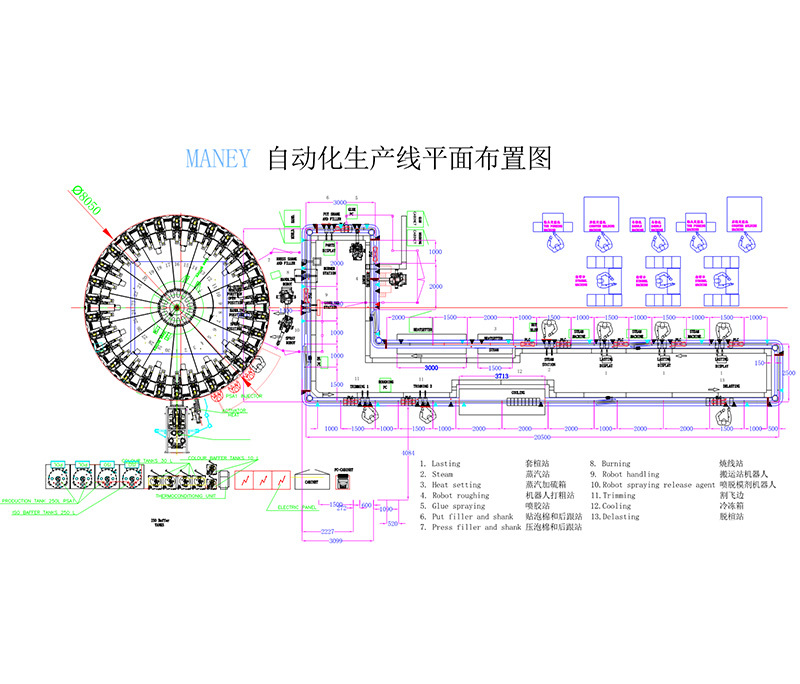

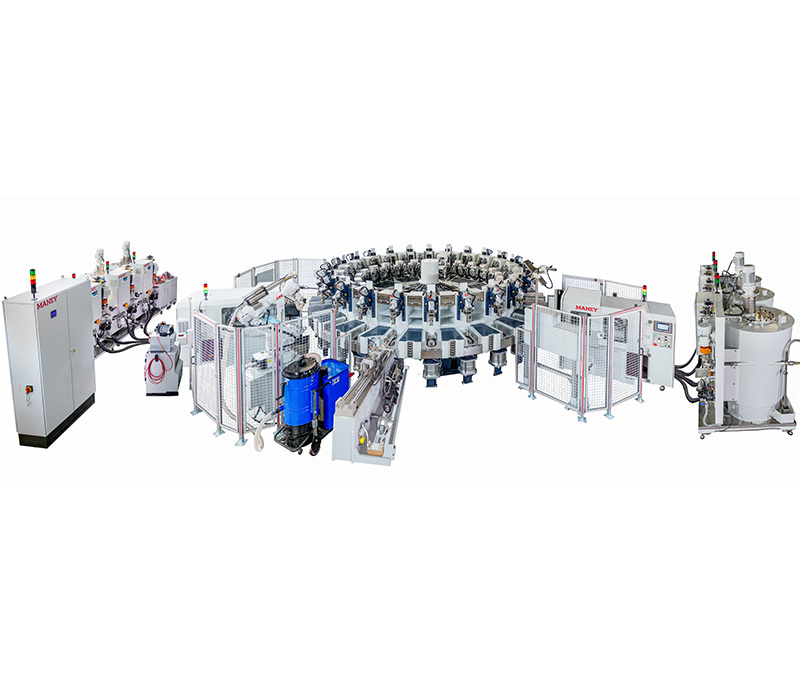

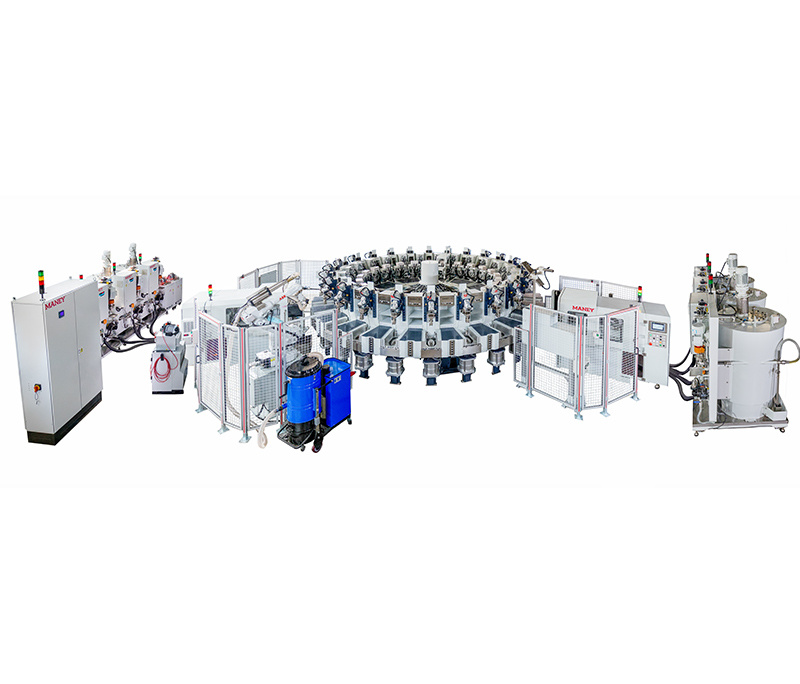

Floor Space

●MY-S818/6: 5.5m*6m ●MY-S818/24: 8m*13.8m ●MY-S818/30:11.5m*10m

| Raw Materials | Single Density | Dual Density | Dual Density Advanced Configuration |

|---|---|---|---|

| PU | MY-B818/30 | MY-E818/30 | MY- S818/30 |

II. "PU/TPU/RU Direct Injection Shoe Making Machine"

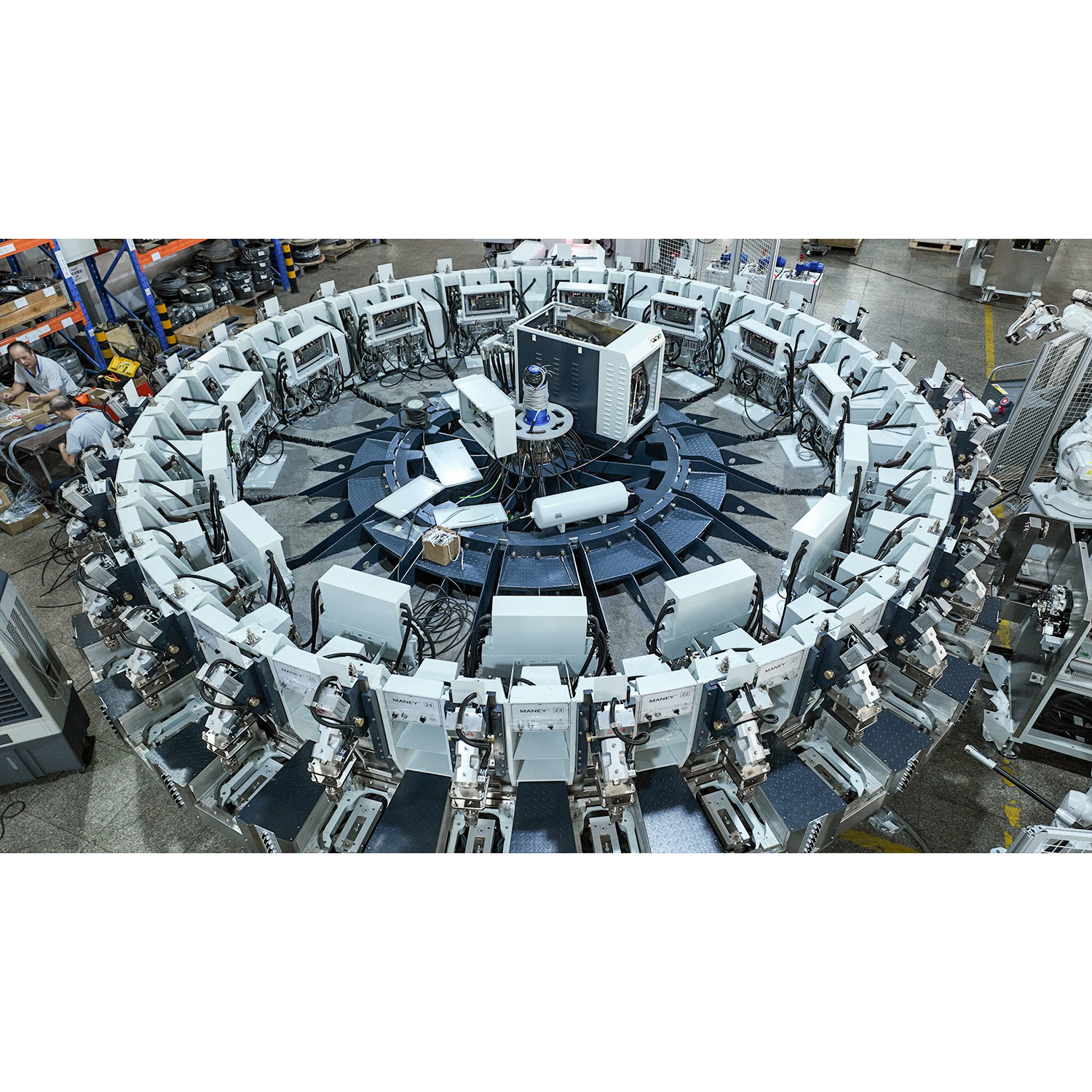

1. Easy operation, reduced labor intensity, high degree of mechanization and automation;

2. The superiority of the injection unit is reflected in the ease of focusing, air trapping, density uniformity, and material replacement;

3. The clamping unit uses imported high-pressure, large-diameter cylinders, ensuring stable vulcanization quality, high output efficiency, and convenient operation;

4. Using high-speed network (Siemens PROFINET or Beckhoff EtherCAT) control technology, it plays a decisive role in machine precision, stability, and energy consumption, making the mechanism movement sensitive and rapid;

5. Using Rexroth pressure-flow proportional control hydraulic system, making the mechanical movement fast, efficient, stable, and energy-saving;

5. Parameters of each station can be freely programmed;

6. Remote control system for machine maintenance and service;

6. PID controlled heating ensures uniform and constant raw material temperature;

7. Using a high-resolution displacement measurement system and material quantity measurement system to ensure the precision and stability of injection movement and injection dosage;

9. Station free programming makes each process simple, intelligent, and flexible.

| Raw Materials | Single Density | Dual Density | Dual Density Advanced Configuration |

|---|---|---|---|

| TPU | MY-C828/30 | MY-D828/30 | MY-G828/30 |

| RU | MY-L858/30 | MY-H858/30 | MY-R858/30 |

Keywords:

Product Inquiry

*Note: Please be sure to fill in the information accurately and keep the communication open. We will contact you as soon as possible.