Intelligent automated forming production line

Share

Product Details

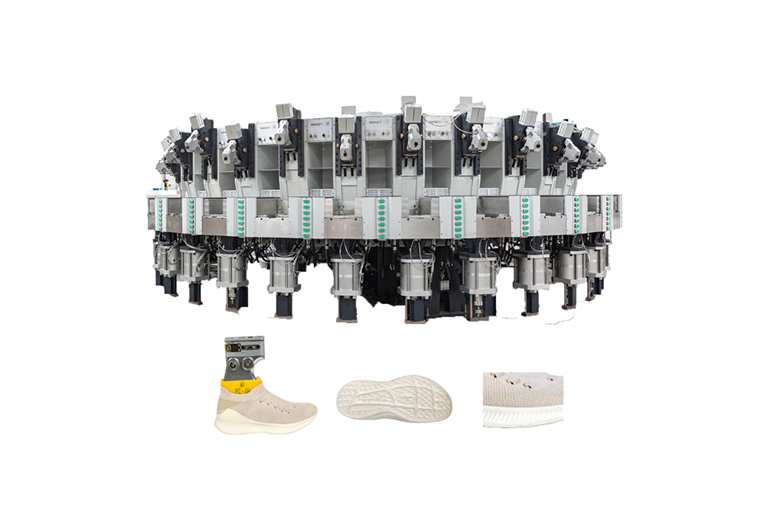

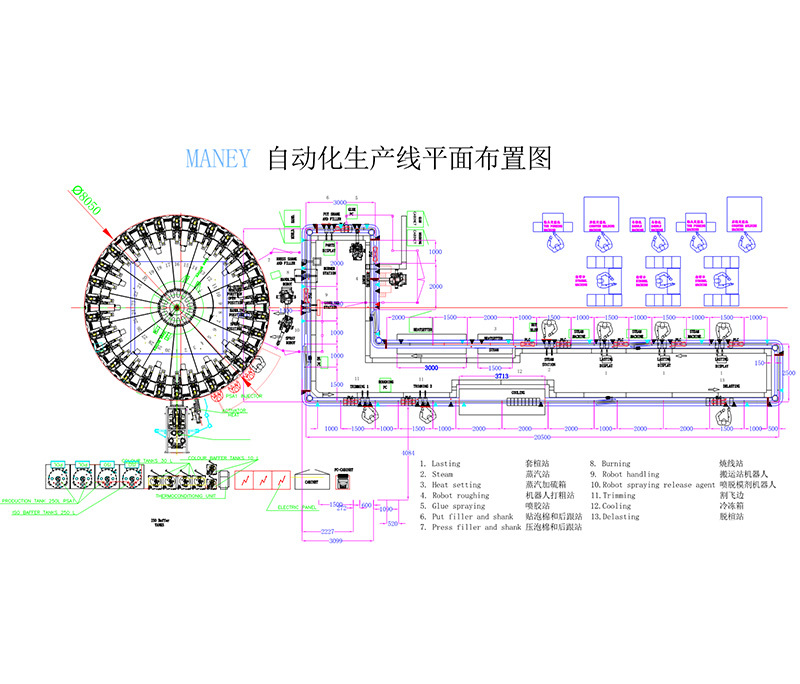

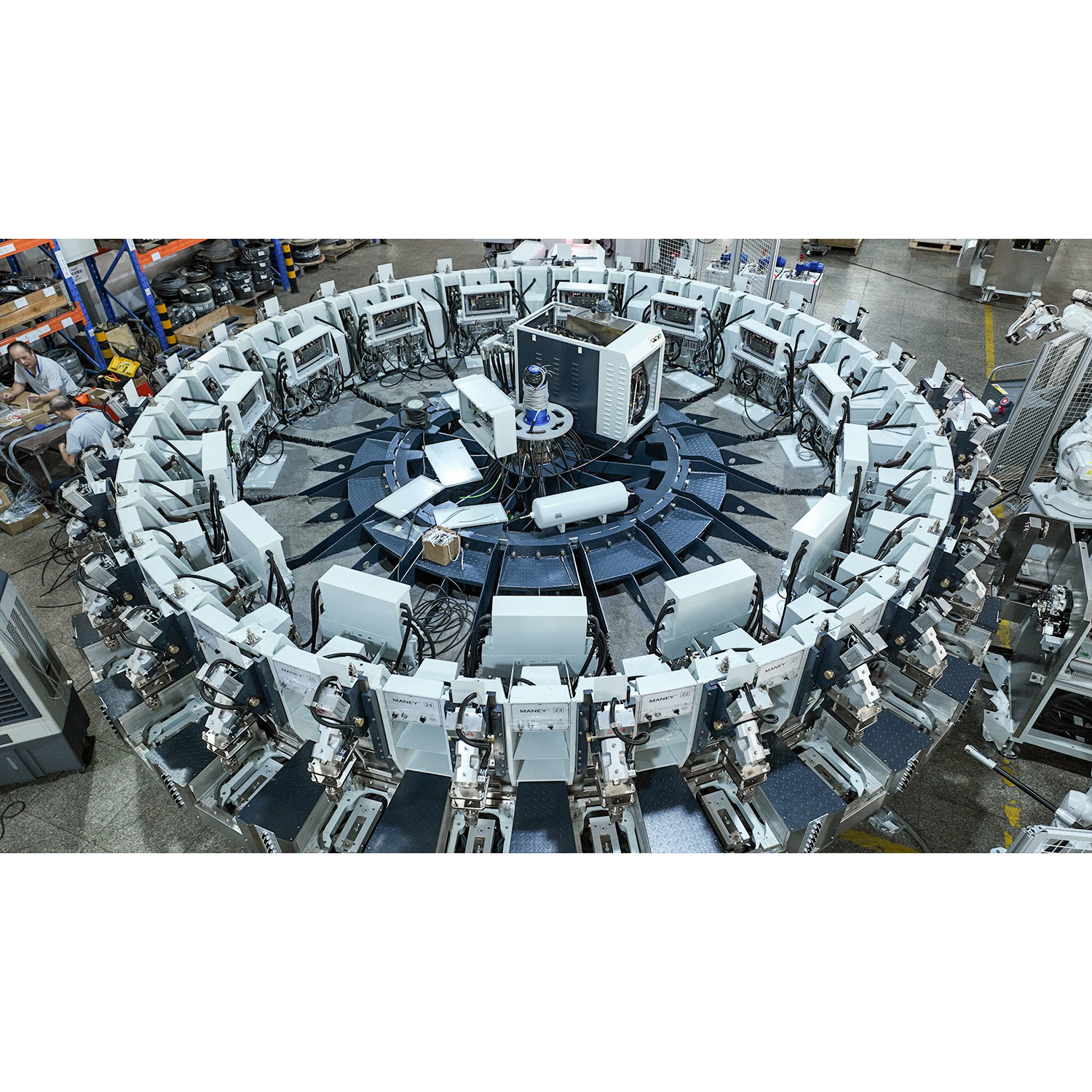

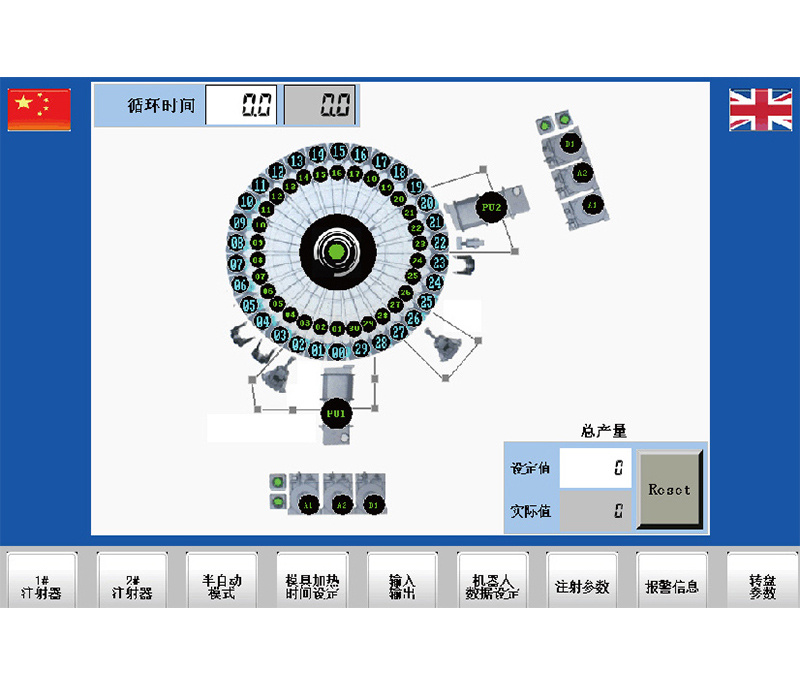

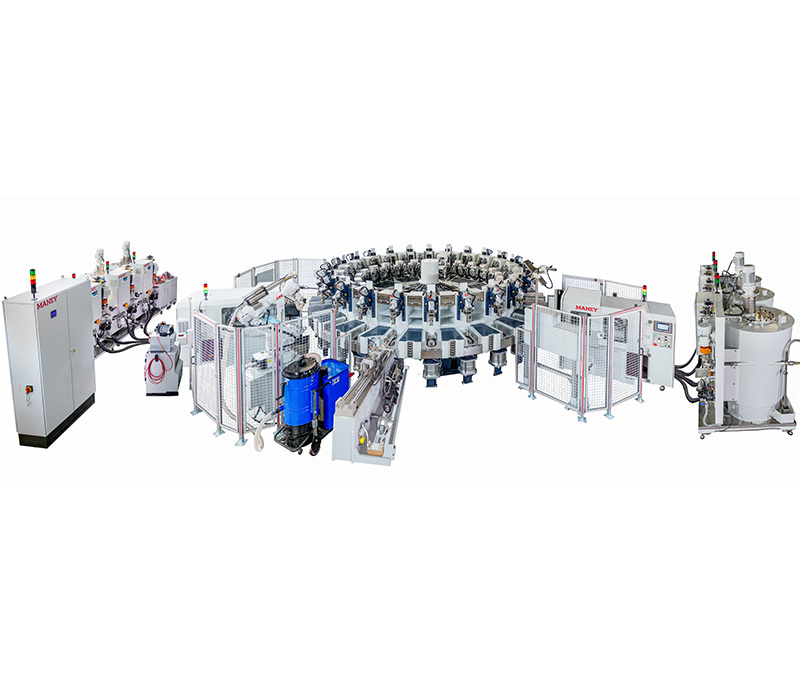

Intelligent Interconnected Automated Shoemaking Production Line

Manyu's intelligent interconnected automated shoemaking production line uses robots to replace manual labor, standardizing operations, reducing fluctuations, increasing speed, and stabilizing quality. In addition to increasing output and saving labor, it fundamentally overcomes the conflict between product cost and diversity in traditional production methods, helping companies achieve improved performance, richer functions, and shorter product development cycles. This is of great significance to the transformation and upgrading of global manufacturing.

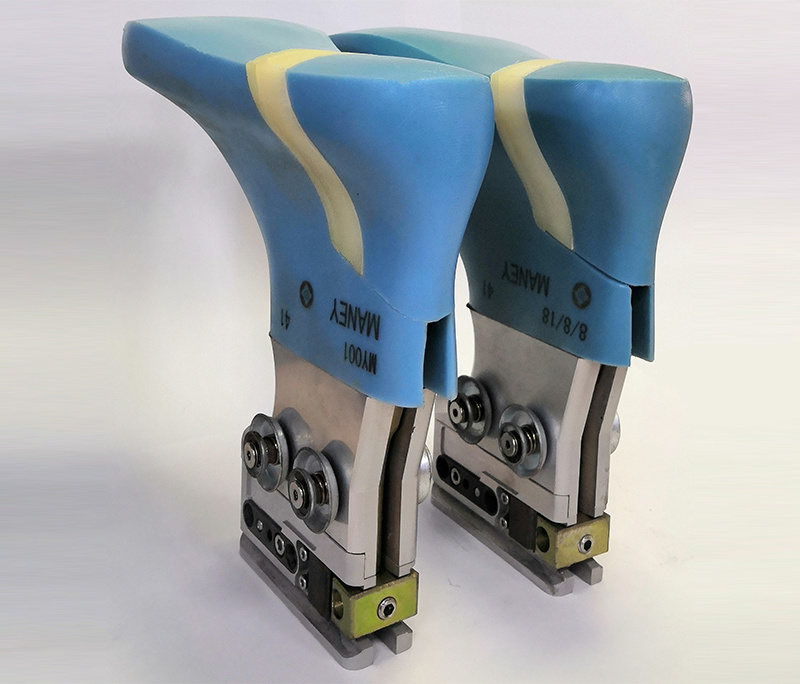

Automated Shoemaking Process with Direct Injection Molding (DIP)

Direction Injection Process (DIP), direct injection molding, is a unique and specialized technology in the footwear industry. Its biggest difference from cold-glued shoes is that it uses environmentally friendly, porous, lightweight, and wear-resistant PU soles that are integrally molded with the uppers in a single injection, eliminating the need for glue or stitching. Therefore, the shape of the DIP sole conforms to human anatomy, with every line and shape designed for a better fit, greater comfort, and improved walking experience. DIP shoes can meet the production needs of various shoe lasts, including formal leather shoes, fashion casual shoes, athletic shoes, hiking boots, and golf shoes. Their smooth, clean appearance, durability, and longevity are unsurpassed.

Attaching the heel counter

Pressing the heel counter

Burning the edges

Pressing the heel

Trimming

Removing the last

Keywords:

Product Inquiry

*Note: Please be sure to fill in the information accurately and keep the communication open. We will contact you as soon as possible.