Precautions during use of Intelligent automatic shoe production line

Publish Time:

2022-08-17

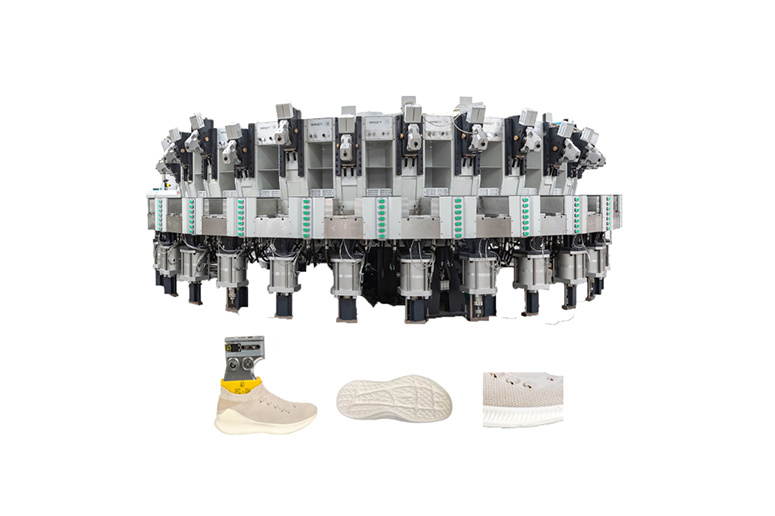

Intelligent automatic shoe production line can help shoe-making companies maximize production efficiency and save a lot of labor costs. What are the main precautions in the use process?

1. Before starting to use the Intelligent automatic shoe production line, first check whether the workshop power supply line meets the load requirements required by the equipment; whether the power supply voltage and frequency are in line with the equipment regulations.

2. The intelligent automatic shoe production line should regularly check whether the assembly of each part is good, whether the fasteners are loose, and whether there are other foreign objects in the body.

3. The intelligent automatic shoe production line should regularly check the connected parts of each wire, whether the connection is reliable and good, and whether there are rust spots and so on.

4.Intelligent automatic shoe production line Before starting the motor, it is necessary to check whether the reducer in the main drive system has been oiled. If not, add No. 30 oil or gear oil above the marking line, and clean it after 200 hours of use. Oil, the shoe machine equipment assembly line is cleaned and changed after every 2000 hours of use.

5. The conveyor belt of the Intelligent automatic shoe production line should be adjusted in time: there is an adjusting screw in the tensioning device at one end of the line, and the tightness of the conveyor belt of the shoe machine equipment assembly line has been adjusted during installation. The wear of each rotating part under the long-term tension working state will cause elongation. At this time, the purpose of tightening can be achieved by rotating the adjusting screw, but it is necessary to pay attention to the appropriate tightness.

6. After each shift of the Intelligent automatic shoe production line is completed, the line body and the sundries under the main and auxiliary machines should be cleaned to keep the equipment clean, tidy and dry to improve the service life of the equipment.