News

The Essential Guide to Pneumatic Punching Machines for Leather Uppers

Pneumatic punching machines for leather uppers are essential tools in the leather processing industry, particularly for manufacturers focusing on footwear production. These machines utilize compressed air to perform precise punching operations, enabling the creation of intricate designs and patterns on leather materials. The use of pneumatic technology not only enhances the speed of production but

08

2025

/

10

Maximizing Efficiency: How Energy-Saving Technologies Transform Injection Molding

Maximizing Efficiency: How Energy-Saving Technologies Transform Injection Molding Table of Contents Introduction to Energy-Saving Technologies in Injection Molding The Importance of Energy Efficiency in Manufacturing Current Energy Challenges in Injection Molding Key Energy-Saving Technologies Revolutionizing Injection Molding Benefits of Implementing Energy-Saving Technologies Re

06

2025

/

10

Understanding Shoe Sole Injection Molding Machines: A Comprehensive Overview

Shoe sole injection molding machines are specialized pieces of equipment designed to fabricate shoe soles through an efficient and streamlined process. This method of manufacturing involves injecting molten material—most commonly thermoplastic elastomers (TPE) or polyurethane (PU)—into a mold that shapes the sole's final form. The process not only ensures precision and consistency in production bu

04

2025

/

10

Discover the Advantages of Utilizing an Automatic Shoe Gluing Machine for Enhanced Efficiency

Discover the Advantages of Utilizing an Automatic Shoe Gluing Machine for Enhanced Efficiency Table of Contents 1. Introduction to Automatic Shoe Gluing Machines 2. What is an Automatic Shoe Gluing Machine? 3. Benefits of Using an Automatic Shoe Gluing Machine 3.1 Enhanced Production Efficiency 3.2 Consistency and Quality of Adhesive Application

02

2025

/

10

Revolutionizing Footwear Production with Automatic Shoe Sole Molding Machines

In the fast-paced world of footwear manufacturing, efficiency and quality are paramount. This is where automatic shoe sole molding machines come into play, revolutionizing the way soles are produced and allowing manufacturers to keep up with market demands. These machines are designed to automate the molding process, significantly reducing production time and labor costs while ensuring high-qualit

30

2025

/

09

The Art and Science of Designing Leather Uppers with Pneumatic Punching Machines

The Art and Science of Designing Leather Uppers with Pneumatic Punching Machines Table of Contents Understanding Leather Uppers: An Overview The Importance of Pneumatic Punching Machines in Leather Crafting Designing Leather Uppers: Techniques and Principles Advantages of Using Pneumatic Punching Machines Operating Pneumatic Punching Machines: Best Practices Innovations in

28

2025

/

09

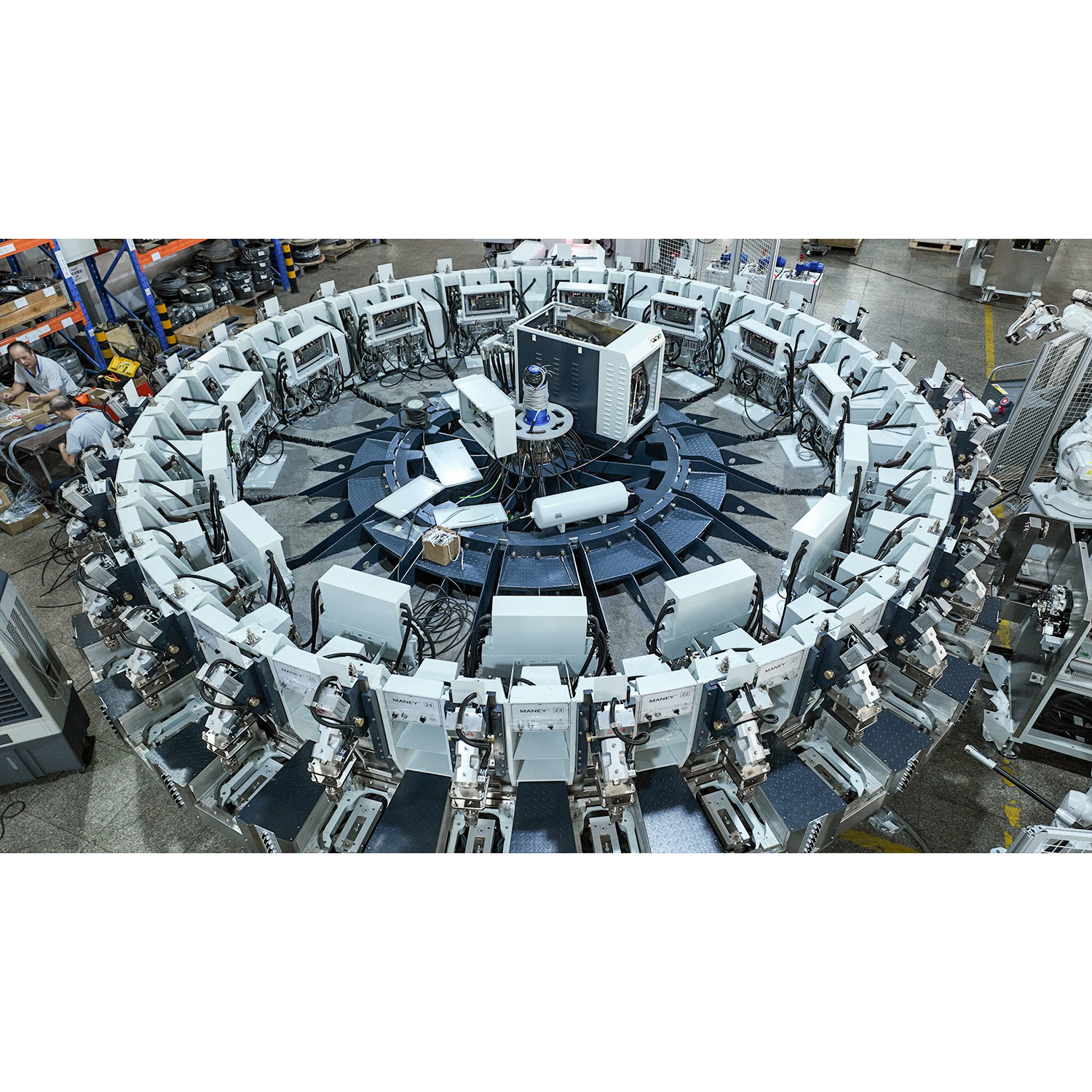

Unlocking Efficiency: The Advantages of Energy-Saving PU Rotary Disc Injection Machines

--- In the rapidly evolving field of plastic processing machinery, energy-saving PU rotary disc injection machines have emerged as a pivotal technology, reshaping production processes across industries. These machines are particularly significant due to their ability to optimize energy use, thereby contributing to both economic and environmental sustainability. The core advantage of energy-saving

26

2025

/

09

Unlocking Efficiency: The Benefits of Shoe Sole Injection Molding Machines

Unlocking Efficiency: The Benefits of Shoe Sole Injection Molding Machines Table of Contents 1. Introduction to Shoe Sole Injection Molding Machines 2. What is Injection Molding? 3. Advantages of Shoe Sole Injection Molding Machines 3.1 Speed and Efficiency 3.2 Design Flexibility 3.3 Material Optimization 4. Applications i

24

2025

/

09