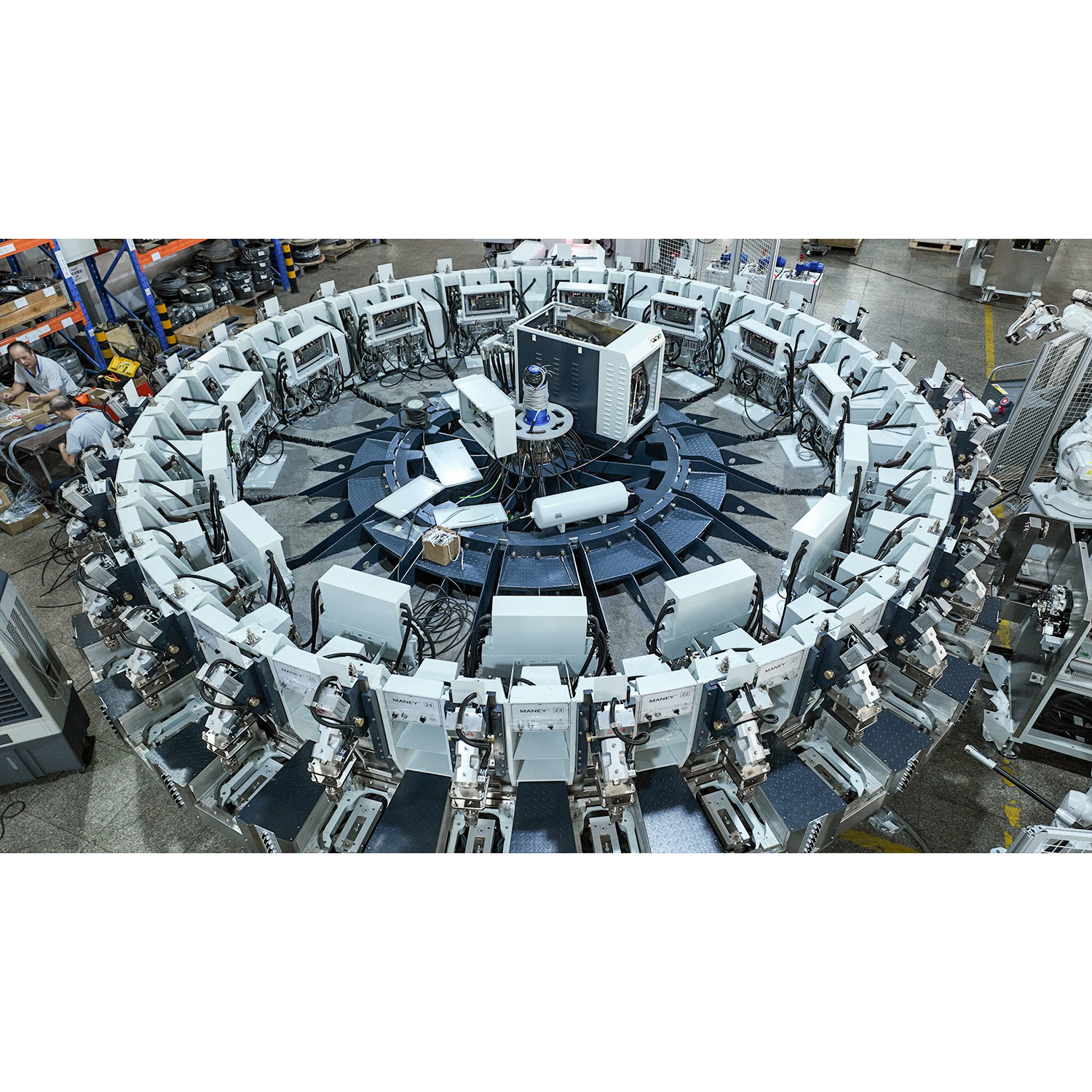

Energy-saving PU rotary disc injection machine

Publish Time:

2025-09-09

In the field of polyurethane (PU) product production, our energy-saving PU rotary disc injection machine stands out with its outstanding performance, providing companies with an efficient and energy-saving production experience.

Energy-saving design reduces costs

The energy-saving PU rotary disc injection machine utilizes advanced energy-saving technology, equipped with a highly efficient heating system and intelligent control system. The heating system precisely controls temperature, reducing energy waste, significantly reducing energy consumption while ensuring production quality. The intelligent control system automatically adjusts the machine's operating parameters according to production needs, ensuring optimal operation at all times, further improving energy efficiency and significantly saving companies significant production costs.

Rotary disc structure for efficient production

The unique rotary disc structure is a major highlight of this injection molding machine. Multiple stations can simultaneously perform different operations, such as feeding, injection, and demolding, ensuring continuous and uninterrupted production. This highly efficient production method significantly improves production efficiency and shortens product cycle times. Compared to traditional injection molding machines, its production efficiency can be increased by over [X]%, meeting the needs of large-scale production.

Precision Injection, Excellent Quality

During the injection molding process, this energy-saving PU rotary disc injection machine achieves highly precise metering and injection control. The advanced metering system ensures the exact amount of PU material injected each time, while injection pressure and speed can be precisely adjusted to product requirements. This results in PU products with high dimensional accuracy, uniform density, and excellent surface quality, effectively reducing defective products and improving overall product quality.

Easy Operation and Easy Maintenance

The user-friendly interface design makes it easy for operators to operate. Clearly explained parameter settings and operating instructions minimize the need for specialized skills. Furthermore, the machine's rational structural design facilitates daily maintenance and upkeep. Components are quick and easy to disassemble and install, minimizing downtime and increasing efficiency. Choosing our energy-saving PU rotary disc injection machine means choosing an efficient, energy-saving, and high-quality production solution that will fuel your business's growth.